RH5 Manus

Humanoid robot as an assistance system in a human-optimized environment

Technical Details

| Size: | 340 x 580 x 1870 mm (on platform) |

| Weight: | 36 kg (excluding platform, equipped with 2x 4-finger-gripper) |

| Power supply: |

48 V, 5 Ah, LiFePo Akku

|

| Actuation/ Engine: |

19x BLDC RoboDrive + HarmonicDrive,

8x RoboDrive + Ballscrew,

3x Dynamixel

|

| Sensors: |

2x ZED Mini stereo camera for object detection

Xsens MTi-300 AHRS IMU

Velodyne LiDAR VLP-16 Puck for mapping and self-localization

ATI 6-DOF force torque sensors (2 pc.) at wrist joints,

Absolute angle measurement in each joint, current measurement enables force control in each joint

|

| Communication: |

LVDS

|

| Motor electronics: |

DFKI electronic stack for all drives:

- Input voltage: 12V-54V

- FPGA- Spartan 6:XC6SLX45

- Serial communication for Spartan-6 (320MSym/s)

- Sinusoidal commutation

- 2 x LVDS for local sensors

- 2 x Ports for IC Haus MU sensors

|

| Gripper: |

optional 2-, 3- und 4-finger-gripper, passiv adaptiv

|

Organisational Details |

|

| Sponsor: |

Federal Ministry for Economic Affairs and Climate Action

German Aerospace Center e.V. |

| Application Field: |

Assistance- and Rehabilitation Systems

Logistics, Production and Consumer Space Robotics |

| Related Projects: |

TransFIT

Flexible Interaction for infrastructures establishment by means of teleoperation and direct collaboration; transfer into industry 4.0

(07.2017- 12.2021)

|

| Related Robots: |

RH5

Humanoid robot as an assistance system in a human-optimized environment

Dual Arm Exoskeleton

Exoskeleton for upper body robotic assistance (Recupera REHA)

|

| Related Software: |

Phobos

An add-on for Blender allowing editing and exporting of robots for the MARS simulation

Rock

Robot Construction Kit

NDLCom

Node Level Data Link Communication

MARS

Machina Arte Robotum Simulans

|

System description

The hybrid serial and parallel design architecture was further developed to optimize weight while increasing stiffness. For improved dynamic behavior, the drive components of the arms were optimized and masses were shifted towards the shoulder joints. The system was equipped with modular grippers which are optionally available in 3 variations as 2-, 3- and 4-finger grippers and can be exchanged with little effort on the robot. The grippers are adaptive and equipped with a haptic sensor system.

Videos

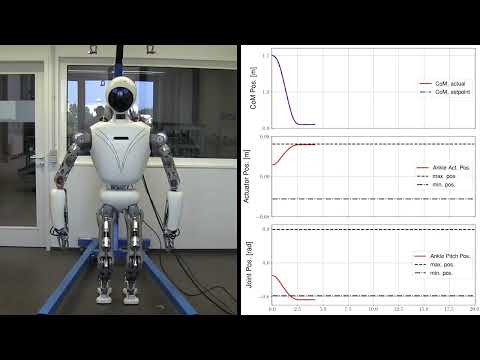

M-RoCK+VeryHuman: Whole-Body Control of Series-Parallel Hybrid Robots

The Video illustrates the results of the paper Dennis Mronga, Shivesh Kumar, Frank Kirchner: "Whole-Body Control of Series-Parallel Hybrid Robots", Accepted for Publication: IEEE International Conference on Robotics and Automation (ICRA), 23.5.-27.5.2022, Philadelphia, 2022.

RH5 Manus: Background of robot dance generation based on music analysis driven trajectory optimization

RH5 Manus: Robot Dance Generation based on Music Analysis Driven Trajectory Optimization

Musical dancing is an ubiquitous phenomenon in human society. Providing robots the ability to dance has the potential to make the human robot co-existence more acceptable. Hence, dancing robots have generated a considerable research interest in the recent years. In this paper, we present a novel formalization of robot dancing as planning and control of optimally timed actions based on beat timings and additional features extracted from the music. We showcase the use of this formulation in three different variations: with input of a human expert choreography, imitation of a predefined choreography, and automated generation of a novel choreography. Our method has been validated on four different musical pieces, both in simulation and on a real robot, using the upper-body humanoid robot RH5 Manus.

RH5 Manus: Humanoid assistance robot for future space missions

The humanoid robot "RH5 Manus" was developed as part of the "TransFIT" project as an assistance robot that can be used in the direct human environment, for example on a future moon station. The aim was to equip the robot with the necessary capabilities to perform complex assembly work autonomously, as well as in cooperation with astronauts and teleoperated. Another focus of the project was on the transfer of the developed technologies to industrial manufacturing and production. The video shows the mechanical assembly and the commissioning of the robot.

RH5 Manus: Introduction of a Powerful Humanoid Upper Body Design for Dynamic Movements

Recent studies suggest that a stiff structure along with an optimal mass distribution are key features to perform dynamic movements, and parallel designs provide these characteristics to a robot. This work presents the new upper-body design of the humanoid robot RH5 named RH5 Manus, with series-parallel hybrid design. The new design choices allow us to perform dynamic motions including tasks that involve a payload of 4 kg in each hand,

and fast boxing motions. The parallel kinematics combined with an overall serial chain of the robot provides us with high force production along with a larger range of motion and low peripheral inertia. The robot is equipped with force-torque sensors, stereo camera, laser scanners, high-resolution encoders etc that provide interaction with operators and environment. We generate several diverse dynamic motions using trajectory optimization, and successfully execute them on the robot with accurate trajectory and velocity tracking, while respecting joint rotation, velocity, and torque limits.

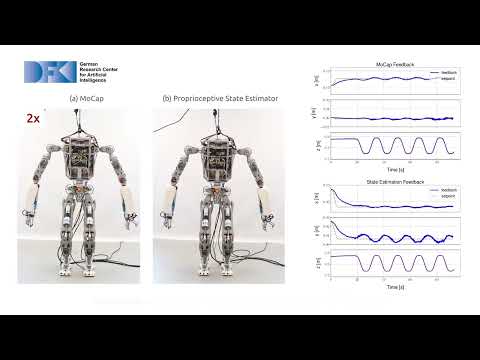

RH5: Motion Capture State Feedback for Real-Time Control of a Humanoid Robot

The Video illustrates the results of the paper Mihaela Popescu, Dennis Mronga, Ivan Bergonzani, Shivesh Kumar, Frank Kirchner: "Experimental Investigations into Using Motion Capture State Feedback for Real-Time Control of a Humanoid Robot", Accepted for Publication: MDPI Sensors Journal, Special Issue "Advanced Sensors Technologies Applied in Mobile Robot", 2022.

RH5: Design, Analysis and Control of the Series-Parallel Hybrid RH5 Humanoid Robot

This paper presents a novel series-parallel hybrid humanoid called RH5 which is 2 m tall and weighs only 62.5 kg capable of performing heavy-duty dynamic tasks with 5 kg payloads in each hand. The analysis and control of this humanoid is performed with whole-body trajectory optimization technique based on differential dynamic programming (DDP). Additionally, we present an improved contact stability soft-constrained DDP algorithm which is able to generate physically consistent walking trajectories for the humanoid that can be tracked via a simple PD position control in a physics simulator. Finally, we showcase preliminary experimental results on the RH5 humanoid robot.